Your shopping cart is currently empty.

![]()

Various nozzle styles are available for different types of car wash applications. Just like picking the right tool from your toolbox – do you need a screwdriver, a hammer, or a wrench? When selecting nozzles, it’s important to understand the type of application it’ll be used in, the quantity and size of nozzles your pump(s) can support, and if there are any important regulatory or water saving considerations.

NOZZLE SELECTION – BY APPLICATION:

Wheels, Rockers, Undercarriage, and Other Blasting

Car Wash Applications:

For high pressure cleaning and blasting applications, we recommend using a rotating or “turbo” nozzle. These types of nozzles blast a 0-degree stream while rotating at an optimized speed to form a cone-shaped spray pattern. The high-impact, pencil-jet style stream blasts away dirt using very little water while the cone-shape covers the vehicle like a flat-fan nozzle.

FEATURED PRODUCT:

What customers are saying - “…the improvement was both immediate and dramatic. Wash quality improved out of sight. The rotating strobe spray pattern of the Hydra-Flex nozzle improved the coverage over the vehicle surface considerably.” –Richard Davison, Shiners Car Wash Systems

Pivoting, Oscillating, or Spinning Car Wash Applications

For pivoting, oscillating, or spinning high pressure vehicle wash applications, we recommend using a zero-degree, solid-stream nozzle due to their high quality streams that stay intact over long distances. These types of nozzles use a concentrated, high-impact 0-degree water jet that attacks tough road grime and easily moves and rinses soap from the vehicle.

FEATURED PRODUCT:

What customers are saying - “Now that we have installed the Blast-Force and Blast-Tec Pro nozzles, our cost of water is about $0.30 per car. Our initial reason for switching to Hydra-Flex nozzles was to save water, and we have already experienced over 30% savings.” –Dan Crader, Best Express Car Wash

Pressure Washing and Industrial Cleaning Applications

For industrial cleaning applications - such as pit cleaning, wall cleaning, and any other off-site pressure washing needs - rotating turbo nozzles which operate at higher pressures (ranging from 1500 to 7500 PSI) are recommended for optimal cleaning results. These nozzles blast a concentrated, high-impact 0-degree water jet while rotating at a high speed to form a cone-shaped spray pattern.

FEATURED PRODUCT:

What customers are saying - “After testing and switching to the Aqua-Rocket, our overall completion time dropped by more than 50%. I can’t speak for everyone, but in our industry this is huge, it enables us to repurpose more than 8 employee man hours for other tasks – resulting in finishing faster and more efficiently!” –Chadwick Kogelschatz, Roskam Baking Company

PROPER NOZZLE SIZING:

Matching Nozzles to Pump

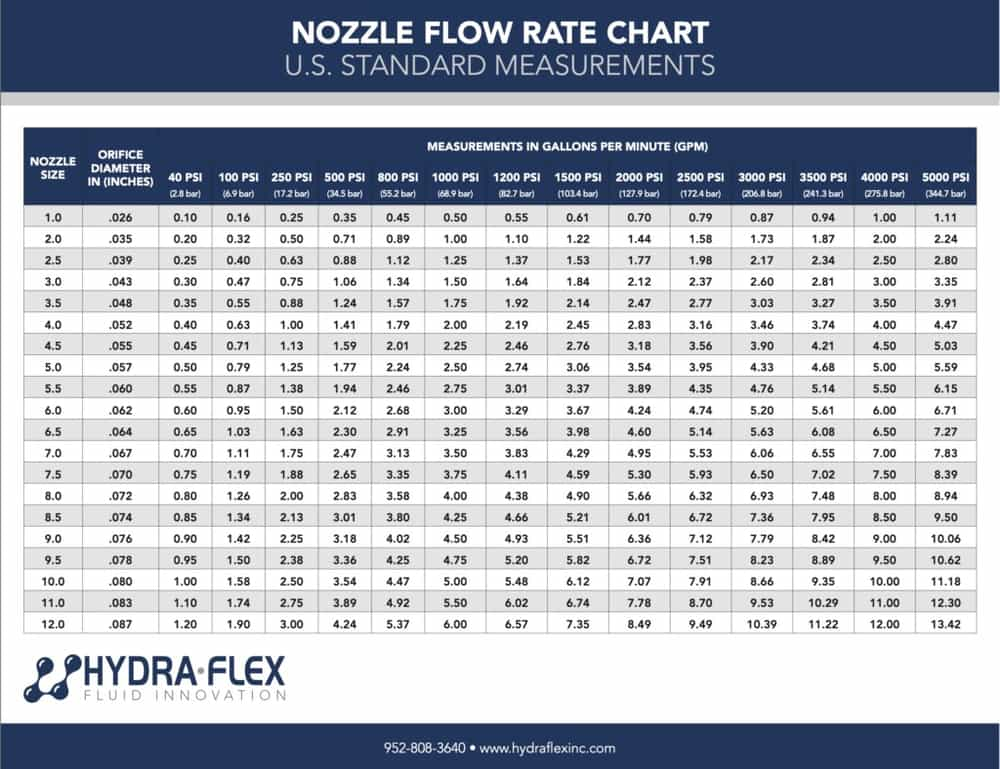

Proper nozzle selection should take into consideration the type of application, your pressure setting, distance from the substrate, and the nozzle number size.

Your pump must be capable of producing the proper amount of PSI needed for the total GPM flow rate of all the nozzles required for the application.

Over and Under Sizing Concerns

Over sizing your nozzle to your pump capacity could result in:

Under sizing your nozzle to your pump capacity may result in: